As massive as the environmental impact of construction is, humans will continue to build. In Canada alone, 22 million houses will be required by 2030 to achieve housing affordability for everyone. Mycelium - the "roots" of things like mushrooms, yeasts, and moulds - may be a viable solution to produce low-carbon and low-impact materials.

The big picture: Construction has a significant environmental impact. It contributes to high energy consumption, greenhouse gas (GHG) emissions, resource depletion, waste generation, habitat destruction, and pollution. Concrete, steel, and other materials are a big part of the issue.

- The construction and operation of buildings, which includes manufacturing of insulation and building materials, is the leading contributor to global energy consumption (36%) and energy-related carbon dioxide emissions (39%)

- Annual global production of cement-based concrete exceeds 33 billion tons, roughly 10000 times the weight of all the blue whales alive

- The cement industry accounts for 8% of global CO2 emissions

The road ahead: Population growth and accelerated economic development will continue to increase the need for construction materials

We must: Coming up with more sustainable materials and manufacturing for the construction industry will have a major environmental impact. We need better construction materials, for yesterday, please, thank you.

Maybe? Mycelium bio-composites are novel materials made from cellulose- or lignocellulose- rich substrates that are embedded by fungal mycelium.

- Although they are mechanically weaker than other insulation materials, mycelium bio-composites are extremely lightweight, with typical densities below 200 Kg/m3, and have excellent thermal and acoustic insulation properties which makes them ideal for construction

- These mycelium bio-composites can act as a net CO2 sink and are more environmentally friendly than commonly used construction and insulation materials

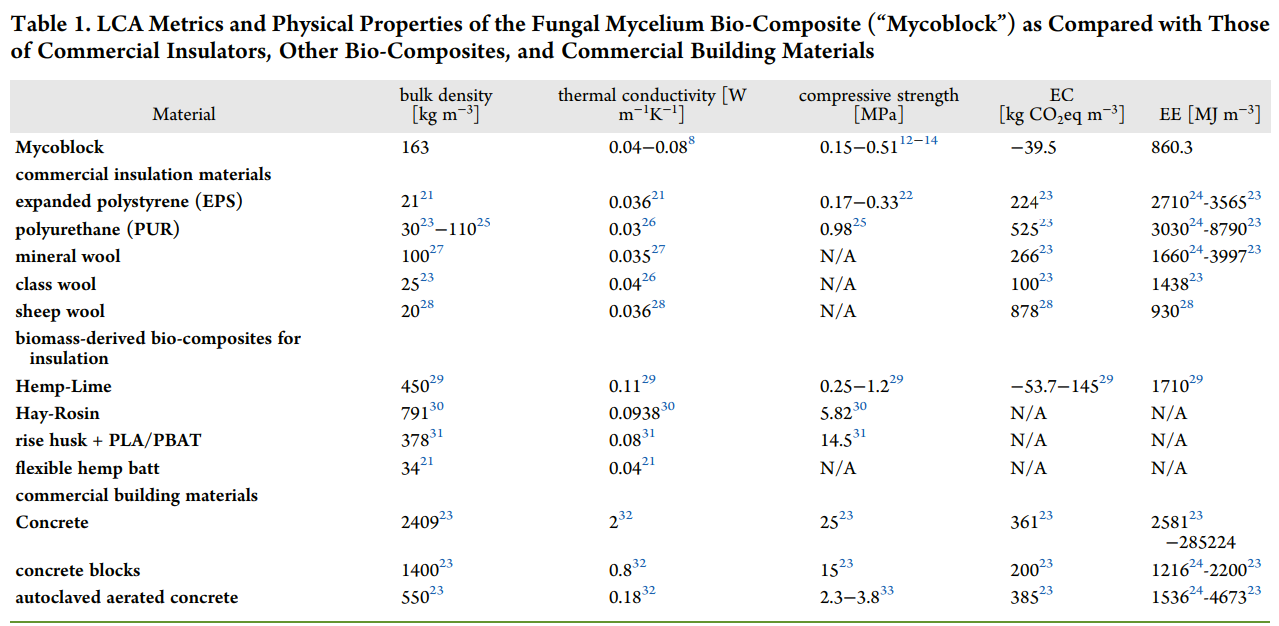

One of many solutions: This table compares the properties of multiple commercial and in-development bio-based insulation materials.

How they know: Comparing the environmental impact of new materials against traditional ones is not easy. A life cycle assessment (LCA) is a tool to quantify the environmental impacts of materials and processes over the life cycle of a product. LCAs can help us make decisions that will benefit the environment.

- The first LCA model of fungal mycelium biocomposites showed an improvement in some environmental criteria, but a worsening in others compared to commercial building materials

- The sequestered CO2 in the substrate and the metabolic CO2 emissions during the fungal growth were left out of the calculations

A new comprehensive LCA model by Achiya Livne at the Ben Gurion University of the Negev included the metabolic fungal GHG emission. They demonstrated that mycelium-based composites have a highly favourable embodied energy (EE) and embodied carbon (EC) for production.

- The EE was estimated to be up to 6 times lower compared with common construction materials

- The EC was calculated to be negative, indicating this material effectively functions as a CO2 sink

- The incubation stage of mycelium bio-composite production made up the largest portion (73%) of the overall energy

- The study shows that using fungal mycelium and local plant residues can provide a sustainable alternative to current construction practices

In conclusion: Mycelium-based materials have tremendous potential in the construction industry, offering sustainable and eco-friendly alternatives to traditional insulation. As research and innovation continue in this field, we can look forward to seeing more widespread use of mycelium in construction projects.

Next door: UBC associate professor, Joe Dahmen, is working on developing mycelium-based materials for construction using additive manufacturing

The source: Fungal Mycelium Bio-Composite Acts as a CO2-Sink Building Material with Low Embodied Energy